In TelesisBio’s recent blog post, they go into discussing how our team partnered with Laurence Warden, Senior Vice President at TelesisBio, Engineering and Instrumentation, to developing a powerful and versatile platform that enables researches to overcome bottlenecks in discovery.

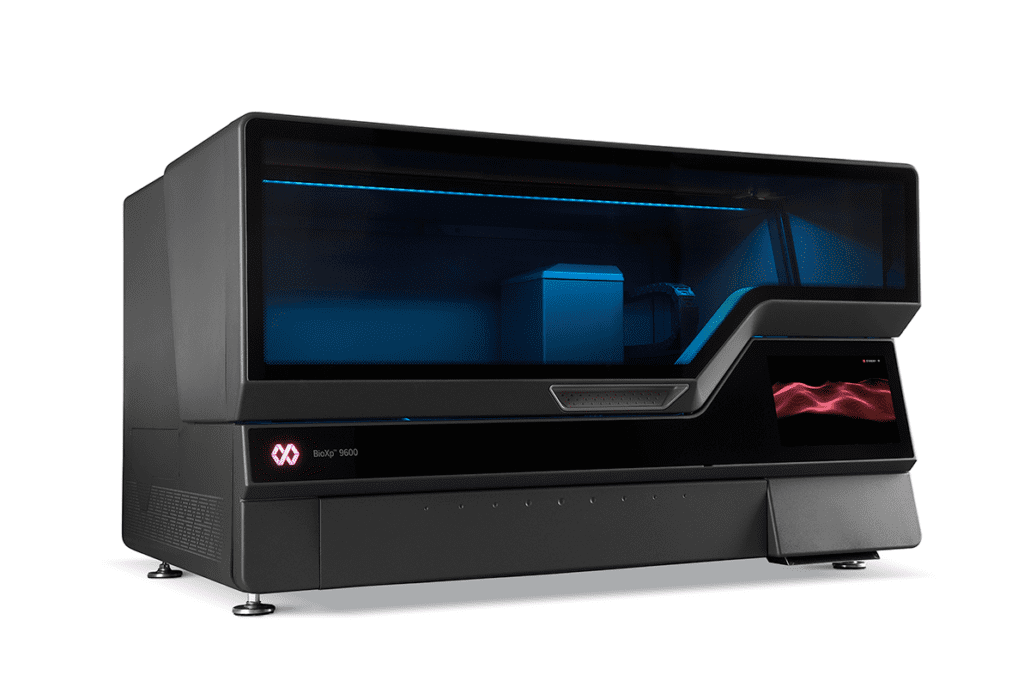

Laurence Warden, Senior Vice President, Engineering and Instrumentation, led his team to develop the BioXp® 9600 system – a high-throughput benchtop platform for synthetic biology workflows designed to empower scientists to accelerate the discovery of new vaccines and biologics. Read how Laurence and his team developed a benchtop instrument that automates synthetic biology to meet customers’ standards of mission-critical development timelines.

1. Tell me about when you went through the process of understanding what you wanted to automate. What was your inspiration? What was your objective? What did you want to achieve?

The development team wanted to create a next-generation platform for the BioXp which would allow for 3X the capacity of the existing 3250 system, allowing researchers to build more constructs in the same amount of time. In addition, we wanted to include the capability of more custom reagents and consumables to run on the instrument which will provide users with even more flexibility when integrating the system into existing workflows. Lastly, the system was designed to connect to future automation, including enzymatic oligo synthesizers.

2. Why is automating synthetic biology challenging?

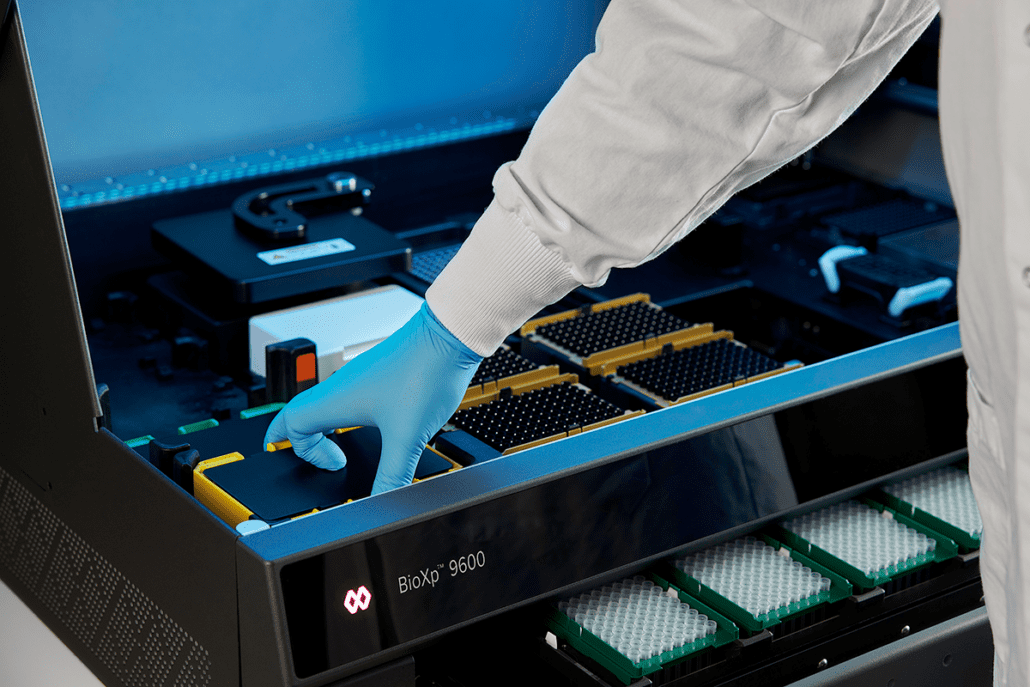

Automating synthetic biology consists of precise fluid handling and accurate temperature control for thermal cycling and reagent storage. Transferring the golden hands of a very experienced molecular biologist can be a challenge. Because the system cannot see to the level of a human, it’s critical to ensure bubbles are not accidentally transferred, or random carryover is avoided at every step. This task can be daunting and requires a close relationship between the engineers developing the software and scripting with the biologist with the golden hands.

3. When you were first thinking about designing and automating synthetic biology as a novel application, what were you the most inspired by?

I’ve always been intrigued by how easily an experienced molecular biologist can cut, splice, amplify, purify and clone DNA. To collapse those steps on an automated platform where its “push button” is a real challenge. It always seemed wasteful to have an experienced biologist doing laborious things, so we aimed to make it as hands-off as possible.

4. You recently led the engineering team that developed the BioXp 9600 — the next-generation high throughput workstation for synthetic biology that builds on the capabilities of the award-winning BioXp platform. How does this version of the BioXp system differ from its previous iteration?

The BioXp 9600 project allowed us to build on the success of the 3250 system. For example, the system can store and use 960 additional disposable tips and has new custom reagent holders and storage for six more processing plates. This process provides flexibility for larger jobs such as mRNA and multi-fragment cloning. We also added bi-direction audio for future on-system training videos and customer service communications.

5. When you set out to design the system, what was your vision for the BioXp 9600?

Our vision for the BioXp 9600 system was that it was easy to use like the BioXp 3250 system but now with added capacity. We wanted the system to be as compact as possible since we know bench space is at a premium with most of our customers. Lastly, we wanted the system to have an attractive and unique industrial design.

6. Is there anything currently comparable to it in the biotechnology market? What would you say sets it apart?

Both the BioXp 3250 and the 9600 are unique in the market. There are many liquid handling systems available on the market, but there are no fully automated DNA assembly systems on the market. What is unique about the BioXp is that the reagents and all the scripting are finely tuned to give users a truly push-button experience for DNA construct synthesis.

7. In terms of design elements, what’s your favorite feature of the BioXp 9600 system?

My favorite feature of the BioXp 9600 is the user interface and how simple it is to use. We redesigned the entire user interface for the 9600 with a beautiful look that matches the industrial design of the enclosure.

8. How do you see this instrument impacting the development of vaccines and therapeutics?

We have been pleased with the response to the BioXp 9600 system. The system provides the capability for our customers to run higher numbers of candidates for screening for vaccines and therapeutics. The BioXp 9600 system is addressing the needs of those customers, helping them to speed up the delivery of these potentially lifesaving products to market.